By Greg Rosalsky / Planet Money

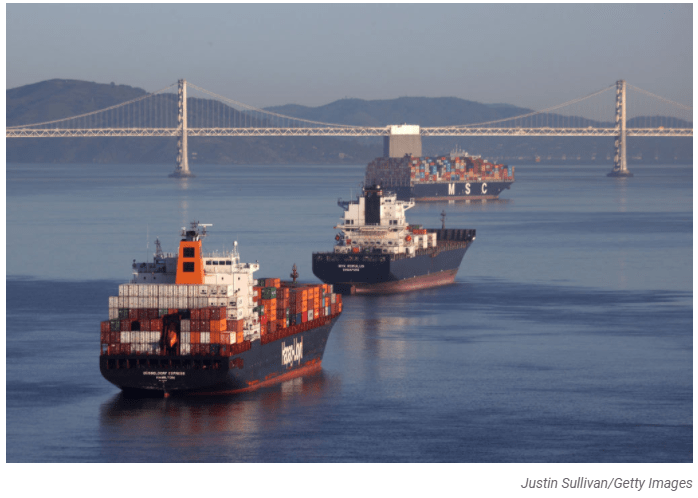

| Whidbey Island is a lovely place about 30 miles north of Seattle on the Puget Sound. Most days the tranquil sounds of rolling waves and chirping birds provide an escape from the hustle-and-bustle of the city. But these days, all is not so serene. Residents are complaining about the ruckus created by humongous container ships anchored off their shore. “We’ve never seen them this close before,” a Whidbey Islander told a local news station. “We’re hearing the throbbing noise at night… It’s a nuisance.” The noise has been so loud that residents have been complaining to the county sheriff’s office about it. Whidbey Islanders are getting a front row seat to the growing U.S. trade deficit, which is hitting record highs. It’s fueled by a surge in demand for imports, mostly from East Asia. There’s so much cargo being shipped to the US from Asia right now that the ports of Seattle and Tacoma are chock-full of container ships. “We are seeing a historic surge of cargo volume coming into our ports,” says Tom Bellerud, the chief operations officer of The Northwest Seaport Alliance, which manages all cargo processing at the ports of Seattle and Tacoma. “The terminals are having a difficult time keeping up with processing all the cargo off these vessels fast enough.” On both land and at sea, the entire supply chain is struggling to keep up. In the Pacific Northwest, it’s become such a clusterfest that the U.S. Coast Guard has been redirecting boats to anchor off the coast of Whidbey Island and other places they typically don’t park. Ship crews are having to wait days, even weeks, for the chance to dock at the ports and offload their precious goods. It’s the same story up and down the West Coast. In the San Francisco Bay, the traffic jam of container ships has gotten so bad that the U.S. Coast Guard has been asking them not to enter the bay at all. Robert Blomerth, director of the USCG’s San Francisco Vessel Traffic Service, said last week that there were 16 container ships waiting in the open ocean outside the Golden Gate to get in and unload their cargo. He says it’s “completely abnormal.” When we spoke to Gene Seroka, the head of the Port of Los Angeles, he said his port had 19 ships waiting to dock, and they’re now waiting, on average, about five days to get in. In normal times, they don’t have to wait at all. |

| Lars Jensen, the CEO of Vespucci Maritime, has spent twenty years studying the industry and he says what’s going on is unprecedented. “The container shipping industry is in a state of chaos that I don’t think it has ever been since it was invented,” he says. The maiden voyage of the first container ship set sail from Newark, New Jersey, back in 1956. It may be hard to fathom just how big a deal this innovation was. It was just a big ship that carried containers, literally metal boxes. But these metal boxes enabled ships to carry dramatically more cargo, and, by standardizing shipping practices and using new machines to handle the boxes, shippers were able to slash costs and the time it takes to load, unload, and transport that cargo. Economists credit these metal boxes with increasing the efficiency of shipping so much that it stitched the modern global economy together more than anything else — more than all free-trade agreements put together. Now economists are concerned that the plumbing provided by these miracle boxes and the vessels that transport them is clogged. It’s making it more difficult for stores to restock their shelves, manufacturers, carmakers, and builders to get the parts they need, and farmers to export their products. It’s an important reason, analysts say, that we’re seeing consumer prices surge. How did shipping get topsy-turvy? In the early days of the pandemic, global trade hit an iceberg and sank into the abyss. The decline of maritime shipping was so dramatic that American scientists saw a once-in-a-lifetime opportunity to study what happened to whales in the absence of a constant deluge of vessels. The noise from the ships apparently stresses them out — kinda like they’re currently stressing out the residents of Whidbey Island. Greater tranquility for whales in the first half of 2020 was the result of shipping companies canceling their trips and docking their ships. Then the economy rebounded, and American consumers unleashed a tidal wave of demand that swept through the shipping industry when they started shifting their spending patterns. Unable to spend money on going out, many started spending their money (and their stimulus checks) on manufactured goods — stuff that largely comes from China on container ships. At first, it wasn’t the ships that were the problem: it was the containers. When the buying spree began, Chinese exporters struggled to get their hands on enough empty boxes, many of which were still stranded in the US because of all the canceled trips at the beginning of the pandemic. More importantly, processing containers here has been taking longer because of all the disruptions and inefficiencies brought about by the pandemic. Containers have been piling up at dockyards, and trains and trucks have struggled to get them out fast enough. “The pandemic has exacerbated longstanding problems with the nation’s supply chain, not just at the ports but in the warehouses, distribution centers, railroads, and other places that need to run smoothly in order for Longshore workers to move cargo off of the ships,” says Cameron Williams. He’s an official at the International Longshore and Warehouse Union, which represents dock workers, primarily on the West Coast. Dock workers have been working tirelessly through the pandemic to handle the increased cargo volume, he says, and at least 17 ILWU workers lost their lives to COVID-19. “We continue to work hard and break records month after month to clear the cargo as quickly as the supply chain allows,” Williams says. It’s been all hands on deck to supply ravenous consumers and businesses with the stuff they want. The resulting traffic jams at West Coast ports means it takes longer to unload stuff, which then extends the time it takes for ships to get back across the Pacific to reload. That congestion was already creating massive delays on both ends of the shipping supply chain, tying up large numbers of containers and ships, leading to growing backlogs and shortages. Then, in March 2021, the Ever Given, one of the largest container ships in the world, got stuck in the Suez Canal in Egypt. While the blockage didn’t directly affect the Asia-West Coast shipping corridor, it added to the global shortage of ships and containers by stranding even more of them out at sea. As if all this weren’t enough, last month there was a COVID-19 outbreak at the Yantian International Container Terminal in China, which is normally one of the busiest ports in the world. The Chinese government implemented stringent measures to control the outbreak, and as a result, more than 40 container ships were forced to anchor and wait. “In terms of the amount of cargo, what’s going on in South China right now is an even larger disturbance than the Suez canal incident,” Jensen says. The Effects On The American Economy With so much shipping capacity bogged down, importers and exporters have been competing for scarce containers and vessels and bidding up the price of shipping. The cost of shipping a container from China/East Asia to the West Coast has tripled since 2019, according to the Freightos Baltic Index. Many big importers pay for shipping through annual contracts, which means they’ve been somewhat insulated from surging prices, but they are starting to feel the pain as they renegotiate contracts. Rising shipping costs and delays are starving the economy of the stuff it needs, contributing to shortages and inflation. It’s not just consumers and retailers that are affected: American exporters are complaining that shipping companies are so desperate to get containers back to China quickly that they’re making the return trip across the Pacific without waiting to fill up containers with American-made products. That’s bad news for those exporters, and for America’s ballooning trade deficit. As for when it’s going to get better, none of the people we spoke to believe it’ll be any time soon. The crazy part of all this is it’s not even considered peak season for the shipping industry yet. That typically begins in August, when American stores start building their inventories for the back-to-school and holiday seasons. The residents of Whidbey Island may have to continue dealing with the nuisance of gigantic, noisy ships cluttering up the horizon for the foreseeable future. |

Post Credit: The Post How “Chaos” In the Shipping Industry Is Choking The Economy first appeared in NPR on 15th June 2021